Conservation, Water Quality Style

Written by Karen Sprague, Water Quality Tech

“What do you know about Affinity Laws?” My boss asked me this question after I had asked why we were installing a different type of pump on a filtration system in the Children’s Zoo. I am an aquatic biologist/water chemistry tech… the answer to his question was “next to nothing.” So he began to explain to me one of the most powerful sets of equations in the realm of hydraulics, and along with them a means to save energy and money and lessen our carbon footprint.

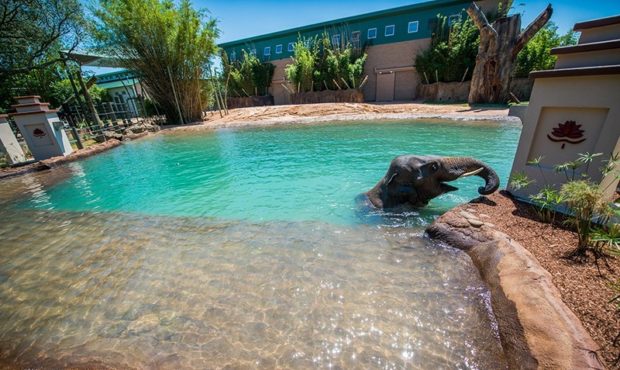

You may be asking yourself “what in the world does this have to do with animals at the Zoo?” Quite a lot, actually! At the Houston Zoo, we provide naturalistic habitats so that our animals may exhibit behaviors just as they do in nature. Often, those habitats include pools: a pool for our Sea Lions to swim in, a pool for our Elephants to take a dip in, a pool for our Flamingos to feed and bathe in – the list goes on and on. The water in these pools is maintained and monitored closely to ensure we provide the best environment possible. In very small pools, zookeepers can drain, disinfect, rinse and refill on a daily basis, but this is not an effective method for the larger pools… for these we need filtration. This is where the Water Quality department comes in.

With a large volume pool comes a large and often complex filtration system that runs 24/7. In order to operate these systems, we need large pumps, and in order to run the pumps, we need electricity – a lot of electricity. Enter the VFD, or Variable Frequency Drive. When designing our new 160,000 gallon Asian Elephant pool filtration system, my boss chose two centrifugal pumps powered by 10 horsepower (HP) motors and controlled by a VFD. With a VFD, one can change the speed of the motor, the rate of water flow in the filtration system, and the consumption of electricity – in a BIG way! Lets take a look at an example. Uh-oh, here comes the math:

As mentioned above, we are using a total of 20 HP with our 2 pumps for the Elephant pool and they run 24/7 – let’s figure out their energy consumption and how much they cost to operate on a yearly basis if they are running at 100% speed:

A 1HP motor consumes 0.7457kW (kilowatts) of energy per hour; 20HP uses 14.914kW per hour. Multiply 14.914kW by 24hrs and you get 357.936kWh (kilowatt hours) used per day. But what does that cost?

Lets say the average cost for a kilowatt hour in Houston is eleven cents:

357.936kWh x 0.11= $39.373/day. Multiply that by 365 days – it costs $14,371.13 per year to operate both of our elephant pool pumps. That’s a big chunk of change, but proper filtration and good health are things our animals cannot live without. Save us Affinity Laws!!

Here’s where things get either interesting or terrifying (depending on your math abilities), but one thing is for sure – we’re going to save energy and money. The Affinity Laws include equations that can help calculate all sorts of things by manipulating variables in pump operation, but we will just use one today: Energy Consumption = (Shaft Speed %)3. HUH? If you’re not an engineer, let me simplify this for you in the way my boss did to help me understand.

Energy consumption of a pump running at full speed, meaning 100% speed:

(1)3 = 1 x 1 x 1 = you guessed it… 1

And $14,371.13 per year x 1 equals – drumroll, please! – still $14,371.13. Bummer.

But what if we decrease the pump speed to a level at which we still get the water flow that we need through our filtration system? For the Elephant pool, the magic number is 83%:

Energy Consumption is now (0.83)3, 0.83 x 0.83 x 0.83 = 0.57, or 57%.

And $14,371.13 per year x 0.57 equals – whoa!!! – $8191.54.

By simply reducing the pump speed to 83% we save $6180 and reduce our energy consumption by 56,178.06 kWh per year. And at 1.6 pounds of carbon dioxide (CO₂) emitted per kWh, we have also reduced CO2 emissions by 44.9 tons per year!

Reducing our carbon footprint by 44.9 Tons of CO₂ per year!

To recap – in this particular example, we have a nice clean pool, we have happy elephants, and math and physics just substantially reduced our carbon footprint. This is good for the environment, and good for animals in wild places! And that, Ladies and Gentlemen, is one big way the Water Quality Department contributes to the Houston Zoo’s conservation efforts. We use VFDs for other exhibit filtration systems too, and as the Zoo’s future renovations take place we will be installing many more, saving money and electricity and reducing our carbon footprint as we go.

**Shout out to the Houston Zoo’s Water Quality Manager, Mike Fannin, for the Affinity Laws tutorial. Kids – if you made it this far… Math and science are your friends! Study hard!